Managing inventory can be a difficult task, especially for small to mid-sized contractors who spend most of their time in the field. Ordering too much product can be expensive and wasteful, but not ordering enough can hold up progress on the job. To help their contractor customers maintain a proper stock level, HVAC distributor Geary Pacific Supply came up with a solution: build an automated inventory replenishment tool.

A custom feature created by Unilog for Geary Pacific’s website, the vendor-managed inventory (VMI) tool lets their customers set quantity thresholds and replenish amounts for the products they regularly stock so when contractors enter their current quantities on hand, the tool calculates how many items to order to adequately restock their supply. Dan Banks, Product Manager at Unilog, says this custom feature is a huge timesaver for contractors, especially those who keep a lot of product in their trucks. “The VMI tool auto-calculates and populates additional stock needed so workers will never be caught with too much – or too little – product on hand,” explains Banks.

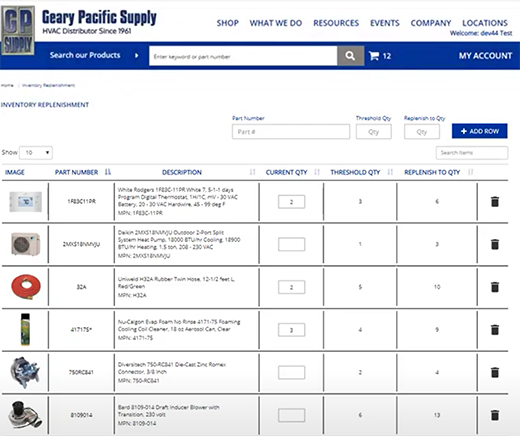

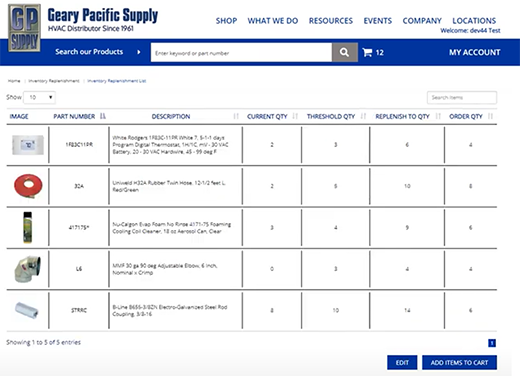

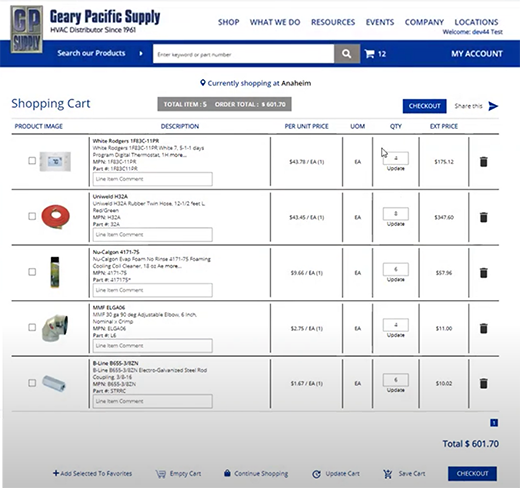

Here’s how the custom feature works:

The customer logs in to the distributor’s site and creates an inventory replenishment list of all their regularly stocked items. Once the list is created, the customer then populates a “Threshold Quantity” (the minimum count of an item that they keep on hand) and a “Replenish to Quantity” (their ideal standard stock level) for each product. This information is saved on the website for them to access at any time. When the customer feels their stock is getting low, they can pull up their inventory replenishment list and enter the current quantities they have on hand for each of their listed products.

Once the Current Quantity field is populated for each item, the customer hits “Submit” and the tool instantly calculates – and populates – the order quantity based on the replenish quantity. When the current quantity drops below the threshold quantity, the Order Quantity field is automatically calculated so the customer reaches their replenish quantity.

The customer adds the items to their cart, reviews the cart, and checks out.

This easy-to-use tool is a big asset to Geary Pacific’s customers, especially since they can access it in the field using their mobile device. To further simplify inventory management, distributors can add the optional SalesRep feature to their eCommerce site, which allows their sales reps to log in as their customers and manage their inventory for them. With the customer’s consent, the sales rep builds their item order list, then visits the customer’s warehouse regularly to input their current inventory numbers into the VMI tool and place their orders. While the VMI feature by itself is a great addition to your eCommerce site offerings, combined with the SalesRep feature, VMI is the perfect solution for distributors looking to provide additional value-added service for their customers.

While the VMI feature has brought efficiency for HVAC contractors, Banks says this functionality can be helpful for any B2B buyer. “I know distributors in other verticals will find this feature valuable because, like Geary Pacific, their buyers don’t want to worry about having too much or too little inventory,” remarks Banks. “The VMI tool is a great option because it always keeps them sufficiently stocked.”

Unilog can build this functionality into existing customers’ sites or new website implementations, so if you’re interested in learning how to integrate this item replenishment tool into your digital branch, contact us today.